Cementing software

Cementing is the process of displacing drilling fluids with cement slurry. A successful cement job is one of the most important factors to the productive life of any well.Complete and durable zonal isolation is the foremost goal of a cement job.

Poor planning and operational execution can not only lead to cement failure but can result in the loss of hydrocarbon recovery from the wellbore.

Some of the challenges that oil and service companies face today include U-tubing, high ECD, loss of circulation and excessive pump pressure, temperature prediction, etc.

These concerns can be best analyzed using computer models, which allow the engineers to see the efforts of different design parameters prior to the job. Potential problems can be identified and the cementing design can be tuned before the pump starts.

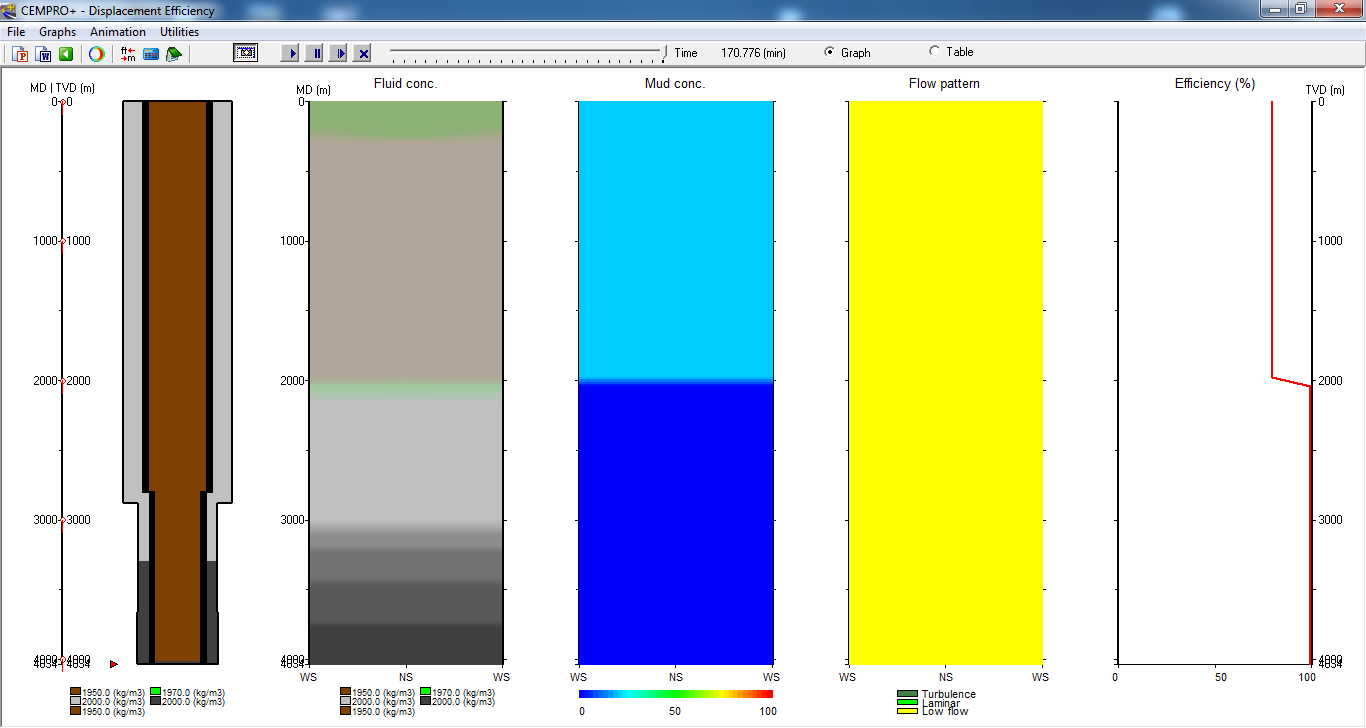

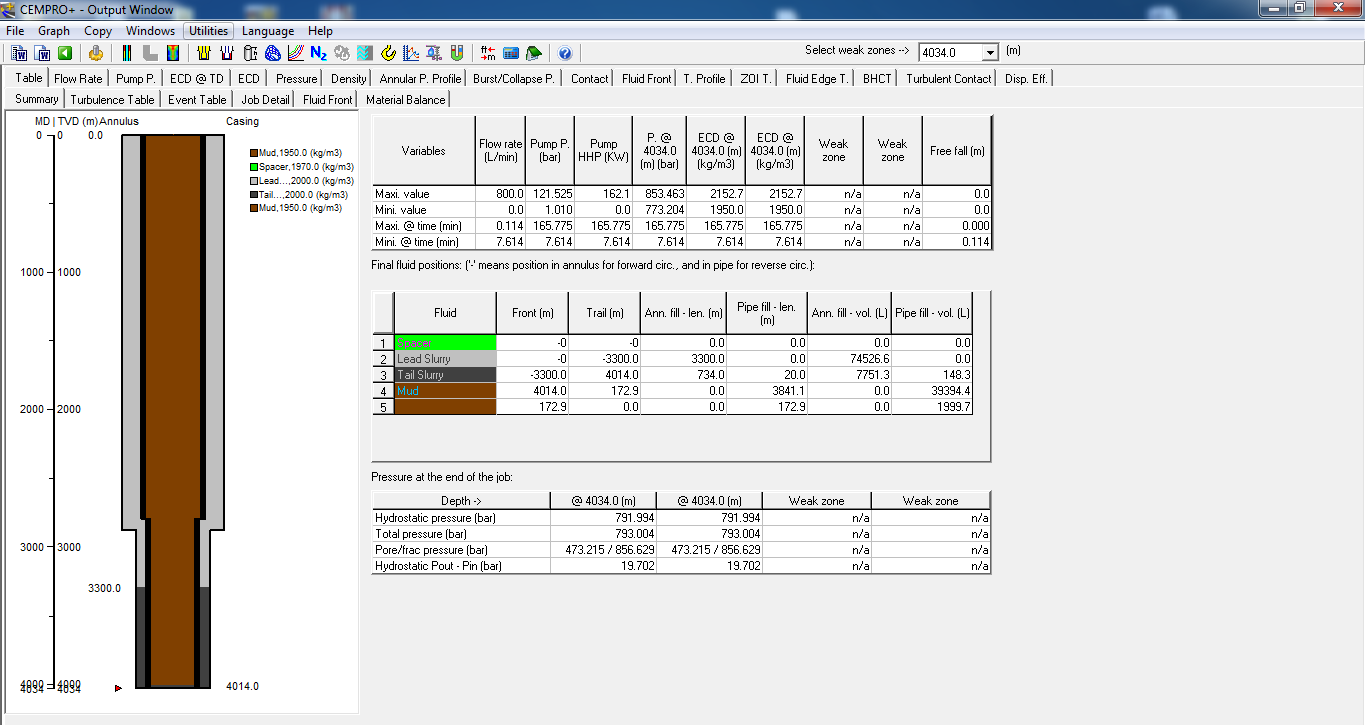

The CEMPRO+ computer program enables pumping companies and operators to provide the best in technical expertise at all levels.

The benefits of using computer modeling

Excellent planner

The software allows engineers to see big and complete pictures at the design stage. It reduces rig time by looking at the pump requirement for the particular wellbore configuration, slurry properties and operation parameters.

Reduce risk

CEMPRO software allows you to see the effects of various cement job design parameters before the job is actually performed. That way, many potential problems can be identified before the pumping starts, and appropriate modifications can be made. Lost circulation, fluids migration, poor cement bond, or slurry contamination can be avoided or minimized.

Safer operation

Having a standard software application provides consistency and confidence in results and helps reduce unnecessary errors which could jeopardize cementing operations. Software tools help foretell well behavior with enough notice to allow cementing teams to calmly make sound technical decisions that lead to a safer operation.

CemCADE (Cementing Computer Aided Design and Evaluation) is a Schlumberger software program aimed at optimizing the design of cementing job operations based on a given set of well conditions.

The well parameters include tubular diameters, hole geometry and trajectory, mud properties and lithology, and pore and fracturing pressures. Once the well parameters are known, job parameters (including fluid densities, rheologies and volumes, centralization program, and pumping flow rates) are optimized for a predefined objective.

The software also checks that the operation can be performed under safe conditions.

These safety checks relate to:

- Tubular integrity (burst and collapse pressures)

- Well security (pore and frac pressures)

- Casing pump-out forces due to buoyancy force